Product Description

Soft Magnetic Alloys Rods, Bars, Sheets, Plates, Strips, Foils, Wires

Soft Magnetic Alloy Rod, Bar, Sheet, Plate, Strip, Foil, Wire

Hiperco 50A

HiperCo 27

HiperCo27 alloy is an iron-cobalt-chromium soft magnetic alloy possessing the highest degree of ductility and toughness

in the commercially available iron-cobalt grades of high saturation and high Curie temperature soft magnetic alloys.

Although the permeability and coercive force of HiperCo 50 alloy are somewhat better than HiperCo 27 alloy,

the magnetic saturation of both alloys is nearly identical. In addition, HiperCo 27 alloy does not exhibit the brittleness

of HiperCo 50 alloy.

Forms: Sheet/Plate, Bar/Rod/Coil

DESCRIPTION

HiperCo27 alloy is an iron-cobalt-chromium soft magnetic alloy possessing the highest degree of ductility and toughness

in the commercially available iron-cobalt grades of high saturation and high Curie temperature soft magnetic alloys.

Although the permeability and coercive force of HiperCo 50 alloy are somewhat better than HiperCo 27 alloy,

the magnetic saturation of both alloys is nearly identical. In addition, HiperCo 27 alloy does not exhibit the brittleness

of HiperCo 50 alloy.

APPLICATION

HiperCo27 alloy has been used in applications requiring a combination of good mechanical toughness, good ductility and

high saturation induction. Examples have included motors, generators, pole pieces, relays and magnetic shaft.

Alloy 79

Alloy 79 is a soft magnetic alloy consisting of 80% Nickel, 5% Molybdenum, and balance Iron used where extremely

high initial & maximum permeability and minimum hysteresis is needed.

Forms: Sheet/Plate, Bar/Rod/Coil

DESCRIPTION

A soft magnetic alloy consisting of 80% Nickel, 5% Molybdenum, and balance Iron used where extremely high initial &

maximum permeability and minimum hysteresis is needed.

APPLICATION

Electro-magnetic shielding, specialty transformer laminations, toroidal tape wound cores, high quality motor laminations,

stepping motors.

Cross Reference

IEC Russia U.S.A Japan

E11c 79HMA Mumetal Supermalloy PCS

65-Permalloy

65-Permalloy has a hysteresis loop and high saturation induction intensity. 65-Permalloy working in a secondary magnetic

field of magnetic amplifier,chock coil,and computer components,etc.

Forms: Sheet/Plate,Wire,Bar/Rod/Coil

DESCRIPTION

65-Permalloy has a hysteresis loop and high saturation induction intensity.

APPLICATION

Working in a secondary magnetic field of magnetic amplifier, chock coil, and computer components, etc.

Cross Reference

IEC Russia U.S.A Japan

E32a 65?? 65-Permalloy PE

12Alfenal

Fe-Al alloys contain 6% to 16% aluminum , the rest elements is the iron. The alloys have high resistivity, lower density

and higher hardness of soft magnetic alloy. This family of alloy is suitable for the special environment

(such as nuclear radiation, shock, acceleration, etc.), and resistance to corrosion and oxidation resistance are better

than those of nickel-iron&soft magnetic alloys, and silicon steel.

Forms: Sheet/Plate, Bar/Rod/Wire/Coil

DESCRIPTION

Fe-Al alloys contain 6% to 16% aluminum , the rest elements is the iron. The alloys have high resistivity, lower density

and higher hardness of soft magnetic alloy. This family of alloy is suitable for the special environment

(such as nuclear radiation, shock, acceleration, etc.), and resistance to corrosion and oxidation resistance are better

than those of nickel-iron&soft magnetic alloys, and silicon steel.

APPLICATION

Fe-Al alloys have accessed to a broad industrial application in the fields of aviation, space flight, navigation,

and other civilian and military industries.

Cross Reference

Russia U.S.A Japan

?12 12Alfenal Hypermal

430FR

430FR is corrosion-resisting soft magnetic Fe-Cr alloy, which has high magnetic induction,low coercive force as well as

high resistivity. It is mainly used as magnetic material in all kinds of electromagnetically operated valves in contact with

corrosive medium as well as in the electro-hydraulic valve of aeroengine.

Forms: Bar/Rod

DESCRIPTION

This material is corrosion-resisting soft magnetic Fe-Cr alloy, which has high magnetic induction, low coercive force

as well as high resistivity.

APPLICATION

It is mainly used as magnetic material in all kinds of electromagnetically operated valves in contact with corrosive medium

as well as in the electro-hydraulic valve of aeroengine.

Soft magnetic Iron Cobalt alloy ASTM A801 R30005 Co49 V2 Fe49

Co49 V2 Fe49 is a high-saturation magnetic induction strength iron-cobalt-vanadium soft magnetic alloy. In the existing

soft magnetic materials, the alloy has the highest saturation magnetic induction (2.4T) and a high Curie point (940?).

Due to the high saturation magnetic induction, when manufacturing a motor of the same power, the volume can be greatly

reduced,and the weight can be reduced, which is less than 50% of that of an ordinary motor. Moreover, the motor has

high sensitivity, low heat generation,good stability and long life. Due to the high Curie point, the alloy can be operated at

higher temperatures where other soft magnetic alloy materials have been completely demagnetized and maintain good

magnetic stability. The performance stability of the motor is better than that of the permanent magnet motor at higher

operating temperatures.

Soft Magnetic -Cobalt Iron Alloy Co49 V2 Fe49

Co49 V2 Fe49 ,Equivalent to Carpenter Hiperco 50,Vacoflux 50, is a high-saturation magnetic induction strength

iron-cobalt-vanadium soft magnetic alloy. In the existing soft magnetic materials, the alloy has the highest saturation

magnetic induction (2.4T) and a high Curie point (940?). Due to the high saturation magnetic induction, when manufacturing

a motor of the same power, the volume can be greatly reduced,and the weight can be reduced, which is less than 50% of

that of an ordinary motor. Moreover, the motor has high sensitivity, low heat generation, good stability and long life.

Due to the high Curie point, the alloy can be operated at higher temperatures where other soft magnetic alloy materials

have been completely demagnetized and maintain good magnetic stability. The performance stability of the motor is

better than that of the permanent magnet motor at higher operating temperatures.

The alloy is melted using Vacuum Induction Melting (VIM) techniques.

Standard Specification :ASTM A801-14 Alloy 1

Alloy 50

A soft magnetic alloy, consisting of 49% Nickel, balance Iron used where high initial permeability, maximum permeability,

and low core loss is needed.

Forms: Sheet/Plate, Bar/Rod/Coil

DESCRIPTION

A soft magnetic alloy, consisting of 49% Nickel, balance Iron used where high initial permeability, maximum permeability,

and low core loss is needed.

APPLICATION

Transformer cores, highly efficient motors, shielding, and specialized electronic devices, such as LF power transducers,

chokes, relay parts, solenoids & oscillators.

Cross Reference

IEC Russia U.S.A Japan

Ella 50H Hy-Ra49 Permalloy PB

Permalloy 80/Mumetal

Permalloy 80/Mumetal is a highly magnetic nickel-molybdenum-iron alloy, with roughly 80% nickel and 15% iron and

5% molybdenum content. It's useful as a magnetic core material in electrical and electronic equipment. Permalloy 80

provides high initial and maximum permeabilities with low coercive force, low hysteresis loss, low eddy-current losses,

and low magnetostriction which is critical for industrial applications.

Forms: Sheet/Plate,Wire,Bar/Rod/Coil

DESCRIPTION

Permalloy 80/Mumetal is a highly magnetic nickel-molybdenum-iron alloy, with roughly 80% nickel and 15% iron and

5% molybdenum content. It's useful as a magnetic core material in electrical and electronic equipment. Permalloy 80

provides high initial and maximum permeabilities with low coercive force, low hysteresis loss, low eddy-current losses,

and low magnetostriction which is critical for industrial applications.

APPLICATION

Transformer laminations; Relay;Recording Heads;Deflection and Focusing Yokes; Amplifiers;Loudspeakers;Shielding.

Cross Reference

IEC Russia U.S.A Japan

Ellc 79HM 4-79 Permalloy -

Mutemp

This is a kind of low Curie temperature (25 ? ~ 200 ?) alloy, its outstanding characteristic is below the Curie temperature,

magnetic induction intensity decreases sharply with the temperature rise, and is almost linear relationship.

Forms: Sheet/Plate, Bar/Rod/Coil

DESCRIPTION

This is a kind of low Curie temperature (25 ? ~ 200 ?) alloy, its outstanding characteristic is below the Curie temperature,

magnetic induction intensity decreases sharply with the temperature rise, and is almost linear relationship.

APPLICATION

Permanent magnet of the traveling wave tube, magnetron,, voltage regulator, mileage rate table, gas table, temperature,

magnetic shunt compensation of watt-hour meter and other components or thermal components.

Cross Reference

IEC Russia U.S.A Japan

- 30H ThermoPerm MS-1

Inspection & Approval Certificates : C/W Certificate (Calibration Works Certificate) EN 10204 3.1 / DIN 50049 3.1 / ISO 10474 3.1 Mill Test Certificate,

NACE HIC TM-0284 / NACE MR-0103 / NACE MR-0175 / ISO 15166, BS EN 9001, BS EN 9100, AS 9100D, IATF 16949, NADCAP Certified, CE Marked,

European Pressure Equipment Directive PED-2014/68/EU, AD-2000-WO, ASME Boiler & Pressure Vessel Code Section-II Part A Edition 2019,

API 6A (American Petroleum Institute), with 3.2 Certificate duly Certified & Approved by IBR (Indian Boiler Regulations), LR Class (Lloyd’s Register),

GL (Germanischer Lloyd), BV (Bureau Veritas), DNV (Det Norske Veritas), ABS Class (American Bureau of Shipping), SGS, TUV, RINA,

IR Class (Indian Register of Shipping), NORSOK Approved Standard M-630, M-650 Rev.3 For Ministry of Defence, DRDO, Indian Ordnance Factory,

Heavy Vehicle Factory, Bharat Electronics Limited (BEL), Hindustan Aeronautics Limited (HAL), Mishra Dhatu Nigam Limited (MIDHANI),

Bharat Dynamics Limited (BDL), Indian Navy (Naval Dockyard), Mazagon Dock Shipbuilders Limited (MDL), Bharat Heavy Electricals Limited (BHEL),

National Thermal Power Corporation Limited (NTPC), Aerospace, Aviation, Electric Vehicles, Armour Vehicle, Armor Vehicle, Automotive, Automobile,

Railways, Medical Equipments, Military Missiles, Energy, Power Sector, Electronics, Power Generation

If you have any requirement of above items, please feel free to contact us

Regards,

CONTACT PERSON :

MUKESH SHAH

Director

Mobile No. 0091 – 9820292499

Email – marketing@rolexmetals.com

ROLEX METAL DISTRIBUTORS

57-A Khatargalli

Thakurdwar

Mumbai – 400 002 India

0091-22-23858802

0091-22-23823963

0091-22-23898724

marketing@rolexmetals.com

www.rolexmetals.com

CHAIRMAN – chairman@rolexmetals.com

MANAGING DIRECTOR – managingdirector@rolexmetals.com

TECHNICAL DIRECTOR – technicaldirector@rolexmetals.com

SALES DIRECTOR – salesdirector@rolexmetals.com

COMMERCIAL DIRECTOR – commercialdirector@rolexmetals.com

COMMERCIAL MANAGER – commercial@rolexmetals.com

GENERAL MANAGER – generalmanager@rolexmetals.com

SALES MANAGER – salesmanager@rolexmetals.com

PURCHASE MANAGER – purchasemanager@rolexmetals.com

TECHNICAL MANAGER – technical@rolexmetals.com

WORKS MANAGER – worksmanager@rolexmetals.com

STORES MANAGER – stores@rolexmetals.com

WAREHOUSE MANAGER – warehouse@rolexmetals.com

SALES DOMESTIC – salesdomestic@rolexmetals.com

SALES INTERNATIONAL – salesinternational@rolexmetals.com

SALES GENERAL – sales@rolexmetals.com

PURCHASE GENERAL – purchase@rolexmetals.com

FINANCE MANAGER – finance@rolexmetals.com

ACCOUNTS MANAGER – accounts@rolexmetals.com

GENERAL INFORMATION – info@rolexmetals.com

EXPORT MANAGER – export@rolexmetals.com

IMPORT MANAGER – import@rolexmetals.com

AIR EXPORT – airexport@rolexmetals.com

SEA EXPORT – seaexport@rolexmetals.com

CUSTOMS – customs@rolexmetals.com

AIR FREIGHT – airfreight@rolexmetals.com

SEA FREIGHT – seafreight@rolexmetals.com

DESPATCH – despatch@rolexmetals.com

INSPECTION – inspection@rolexmetals.com

LOGISTICS – logistics@rolexmetals.com

TRANSPORT – transport@rolexmetals.com

KALAMBOLI WAREHOUSE – kalamboli@rolexmetals.com

TALOJA WAREHOUSE – taloja@rolexmetals.com

KHOPOLI WAREHOUSE – khopoli@rolexmetals.com

NHAVA SHEVA WAREHOUSE – nhavasheva@rolexmetals.com

KANDLA WAREHOUSE – kandla@rolexmetals.com

MUMBAI WAREHOUSE – mumbai@rolexmetals.com

STOCKYARD – stockyard@rolexmetals.com

SERVICE – service@rolexmetals.com

SUPPORT – support@rolexmetals.com

RECRUITMENT – career@rolexmetals.com

WEBMASTER – webmaster@rolexmetals.com

CUSTOMER CARE – customercare@rolexmetals.com

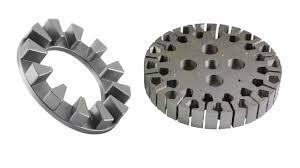

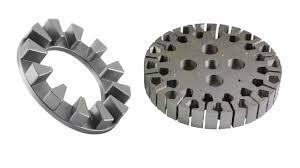

Product Image